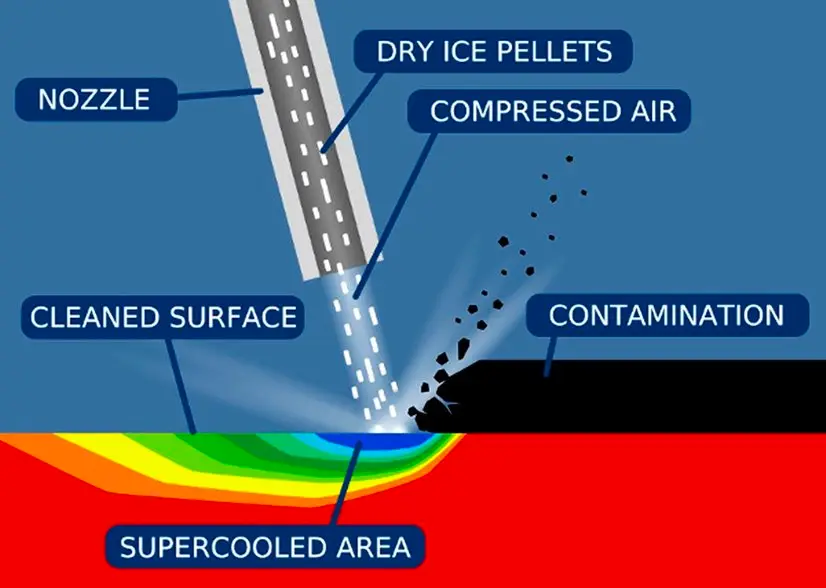

When it comes to industrial cleaning, Blizzard Blasting Solutions turns to the power of dry ice. We blast dry ice pellets (-79c) at the chosen surface using high-pressure air. When the pellets make first contact there is an initial thermal shock that dries and freezes the surface breaking adhesion, resulting in the formation of cracks on the contaminate surface. Following pellets then burst through the surface and expand by 70,000%, through a process called sublimation, blasting any particulates away. Finally, a high-pressure ‘airbrush’ cleans the surface, leaving it appearing like new.

We are a family run business based in Sandy Bedfordshire but we operate nationwide.

How It Works

OUR SERVICES

Dry ice blasting is an environmentally friendly, net zero cleaning method used for industrial cleaning purposes. Listed below are the industries we target.

Grease, wax, proteins, seasonings, crumbs, glue, and other things build up on equipment used to make and package food. This stops the equipment from working as well as it could. Dry ice removes these with ease while disinfecting the surface making it impossible for bacteria to contaminate any product.

Dry ice blasting is also good for removing buildup and other contaminants in small spaces and tight angles. This is because the concentrated stream makes it easy to reach and clean places that are hard to get to. Getting rid of oil, bitumen, corrosive agents, coatings, corrosion, salts that dissolve and chloride.

Dry ice blasting is a safe and effective cleaning method for the energy sector, including nuclear power plants. It cleans turbine blades and cooling systems, enhancing efficiency and dependability. Dry ice blasting cleans radioactive areas without spreading contaminants. With reduced downtime, no chemicals or solvents, and extended equipment lifespan, it enhances operational efficiency, regulatory compliance, worker safety, and environmental sustainability in the energy sector.

OUR SERVICES

Dry ice blasting is an environmentally friendly, net zero cleaning method used for industrial cleaning purposes. Listed below are the industries we target.

Aerospace Industry

We can effectively remove carbon deposits, oil, grease, and other contaminants from engine components like turbine blades, compressors, and combustion chambers. we can clean aircraft interiors, removing dirt, grime, adhesive residues, and even graffiti from surfaces like seats, walls, overhead compartments, and windows.

Food and Drink Industry

Grease, wax, proteins, seasonings, crumbs, glue, and other things build up on equipment used to make and package food. This stops the equipment from working as well as it could. Dry ice removes these with ease while disinfecting the surface making it impossible for bacteria to contaminate any product.

Oil and Gas Industry

Dry ice blasting is also good for removing buildup and other contaminants in small spaces and tight angles. This is because the concentrated stream makes it easy to reach and clean places that are hard to get to. Getting rid of oil, bitumen, corrosive agents, coatings, corrosion, salts that dissolve and chloride.

Spray Foam Insulation Removal

BBS dry ice blasting provides comprehensive spray foam removal for residential and business customers. Because of its compact, closed cell qualities, spray foam locks moisture on roof beams, rafters, and trusses. This may damage the timber below compromising the structure of the building. Spray foam prevents most surveyors from approving mortgages.

Automotive Industry

The process of dry ice blasting may be used on almost all aspects of a vehicle and the manufacture process including wheels, engine blocks, cylinder heads, seat and gasket moulds, weld lines, conveyors, electrical components and motors, welding, fixtures, paint shops, tyre moulds and paint removal. Cleaning up to 75% faster then other cleaning methods.

Bitumen Removal

Dry ice blasting is the best approach to remove bitumen and tar from surfaces in industry, historic structures and houses. Bitumen freezes and fractures when it comes into contact with dry ice pellets (-79 Celsius) during dry ice blasting. Then the frozen gas expands and explodes (known as sublimation). The bitumen separates from the surface, leaving it clean and unharmed.

Equestrian Industry

For stall and stable cleaning we can remove dirt, grime and odours. The procedure uses non-abrasive, non-toxic pressurised dry ice pellets. Its residue-free cleaning is safe for animals. Dry ice cleaning reduces the risk of respiratory and infectious diseases in horses. Saddles, bridles, and bits can collect dirt, sweat, and pathogens. Horse trailers and transport vehicles need frequent cleaning to keep animals healthy.

Energy sector

Dry ice blasting is a safe and effective cleaning method for the energy sector, including nuclear power plants. It cleans turbine blades and cooling systems, enhancing efficiency and dependability. Dry ice blasting cleans radioactive areas without spreading contaminants. With reduced downtime, no chemicals or solvents, and extended equipment lifespan, it enhances operational efficiency, regulatory compliance, worker safety, and environmental sustainability in the energy sector.

Component cleaning

Our company offers a comprehensive component cleaning service utilizing the power of dry ice blasting. With our specialized expertise and state-of-the-art equipment, we can efficiently clean a wide range of components from various industries. You send us what you want cleaned or refurbished via courier and we send it back as soon as it’s completed.

PRICING

We price each job individually with a unique quote. Follow the prices below for an idea of our day rate for each industry.